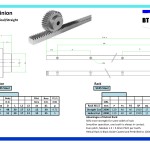

Rack and Pinion

Rack and Pinion in Straight cut and Helical

Module M1.5 ex Stock. Ideal for CNC applications

Rack and Pinion

Rack and Pinion assemblies are utilised to convert rotating movement into linear motion. A gear rack has straight teeth cut into one surface of a square or round section rod with a pinion, which is a small cylindrical gear meshing with the gear rack.

BT Precision has many types of gear racks in stock. If the application requires a long length requiring multiple gear racks in series, we have racks with the tooth forms correctly configured at the ends. These are described as “gear racks with machined ends”.

There are applications where the gear rack is stationary, while the pinion traverses and others where the pinion rotates on a fixed axis while the gear rack moves. The former is used widely in conveying systems while the latter can be used in extrusion systems and lifting/lowering applications.

As a mechanical element to transfer rotary into linear motion, gear racks are often compared to ball screws. There are pros and cons. The advantages of a gear rack is its mechanical simplicity, large load carrying capacity, no limit to the length, etc. One disadvantage though is the backlash. The advantage of a ball screw is the high precision and lower backlash while the shortcomings include the limit in length due to deflection.

Rack Types

Rack and pinion gears are available in two variations:

- Straight teeth have the tooth axis parallel to the axis of rotation. Straight teeth that run parallel to the axis of the gear.

- Helical teeth gears provide continuous engagement along the tooth length and are often quieter and more efficient than straight tooth gears and also offer higher loading for same rack width.. Helical tooth gears resemble spur gears in the plane of rotation, but include teeth that are twisted along a helical path in the axial direction.

Applications

Rack and Pinion drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, travelling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy load capacities and duty cycles can also be easily handled with these drives. Industries served include Material Handling, Automation, Automotive, Aerospace, Machine Tool and Robotics.