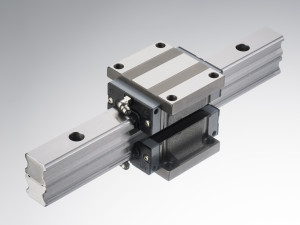

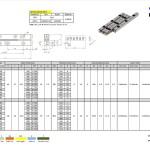

Profile Linear Guides

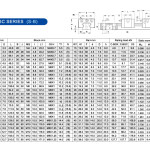

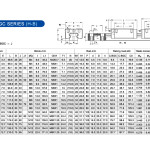

STAF BGX Profile Linear Guides offer High load Capacity, High Rigidity, High Accuracy and smooth Movement in a Standardized design Interchangeable with other brands. STAF Linear Guides feature a Common rail for all series of Bearing Carriages and offer equal load capacities in all directions. Rails are available in Long lengths up to 4 Metres Long and available with short delivery time.

Staf Profile Linear Guides have been standardised into many types and dimensions so that the most suitable products can be selected for all kinds of applications.

Staf Linear Guides have a unit construction making it possible to obtain a high running accuracy without clearance by simple installation with bolts on a flat surface. Results and experience has been obtained for a wide range of applications.

The excellent performance of Staf Linear Guides in many varied applications is due to the following engineering characteristics-

- Staf Linear Guides are of a restraining construction permitting loads in all directions-up and down, left and right, in a single axis. This allows flexible design according to the application.

- The ball tracks in Staf Linear guides are ground to a circular arc groove shape approximating the ball diameter. This allows a wide contact width between the balls and the raceway. This design gives Staf linear guides very high load capacities, long service life and high rigidly can be obtained.

- Staf linear guides have an angular contact ball configuration consisting of 4 rows of balls. This allows a clearance level of zero or below while maintaining smooth movement without ball slippage. This construction also allows preloading of the system for high rigity application such as for CNC machine tools.

- The 4 rows of steel balls in Staf Linear Guides form a 45 degree contact angle with the ball grooves at 4 positions which balance the loads in all directions. This design permits even load capacity in all directions no matter how the rails are mounted and is widely adopted in all types of machines. Compared with the 2 Groove Gothic arch design, the 4 groove construction is of better rigidity, accuracy and life. In particular the’ auto adjust’ capability allows quick accurate linear motion systems by eliminating the deviations of the mounting plane and assembly errors.

Staf linear guide are available in two versions- BGXH -standard type and BGC- caged type. The BGC caged type has all of the advantages of the standard type but with the addition of a polymer cage separating the balls within the bearing body. This allows quieter operation, higher Linear travel speeds and longer life. The Cage( Ball retainer ) allows separation of the rolling elements reducing wear between adjacent balls. This also reduces and noise and facilitates better lubrication of the internal workings of the bearing.

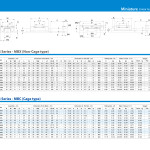

Linear Guides MB Series Miniature

STAF MBX Miniature Profile Linear Guides offer High Precision and High load capacity in an ultra compact design. MBX Miniature Linear Guides are Interchangeable with other brands and come with built in dust sealing. Rails and carriages come standard in Corrosion resistant material in Narrow and Wide Series available with short delivery times.

Staf Miniature Profile Linear Guides are manufactured to Industry standard envelope dimensions into two main types of narrow and wide versions. Staf Miniature Linear Guides incorporate the largest possible ball size in a minimal space achieving high loads and excellent durability in an extremely compact package. To reduce the influence of Inertia moments at high speed the most compact design of Staf Miniature Linear Guides is meeting the demands for smaller, lighter and thinner units.

Construction and Features

Staf Miniature Linear Guides consist of 2 rows of Precision Balls recirculating in a compact construction. There are two versions Staf Miniature linear Guides, standard version MBX and Caged Ball version MBC. The recirculating ball design provides unlimited stroke with smooth motion. The shape of the Staf Miniature Linear guides blocks so that stiffness is obtained with limited space. Staf Miniature Linear Guides maintain high stiffness in all directions due to the large size ball diameter designed into the guide. High load and rigid is especially noted in the MGX and MBC wide series which has increased ball quantity per row and wider bearing body which allows for higher load capacity and better resistance to moment loading.

Loads in all Directions

Staf Miniature Linear Guides are designed to take loads in all direction at right angles to the bearing axis. In case of small moment loads sufficient use can still be obtained from a single bearing.

Corrosion Resistant

Staf Miniature Linear Guides are made from Corrosion resistant material as standard.

GMT Cross Roller Guides

GMT Precision Cross Roller guides are very suitable to Short Travel and Micro movement applications. GMT Cross Roller Guides offer very high load capacity in an ultra compact design. Available in Standard and Corrosion resistant materials. GMT cross Roller Guides are Extremely low friction and offer High rigidity while maintaining smoothness of movement. Also available in ‘XY’ Configuration. See GMT website for details.

GMT Cross Roller guides GRV are a limited stroke type linear motion system offering high rigidity. High accuracy and compact design. GMT cross roller guides achieve high accuracy and high rigidity by using the combination of Rollers and a roller cage running on special V-rail guides which are specially heat treated and precision ground.

These guides are used for many applications providing precision sliding movement in Precision Measuring equipment, circuit board drilling and assembly machines, Automatic lathes, Tool grinders, Internal grinders, small Surface grinding machines, EDM machines, Super finishing machines and medical equipment such as X Ray machines.

Construction and Features

GMT Cross Roller Guides GRV type uses a roller cage with Integral precision rollers staggered at right angles in combination with a V Groove Precision Ground Hardened rail. By installation of 2 rows of roller guides in parallel all loads at a right angle to the axis can be taken up. As preloads can be easily applied, linear motion systems of high rigidity and light movement can be obtained.

Long Life and Smooth Movement

The GMT Cross Roller guide GRV has the rollers separated from each other by a cage, and the roller pockets formed in the cage have surface contact with the rollers which facilitates lubrication ensuring smooth movement and with little wear and very low friction.

Corrosion Resistant Version

GMT Cross roller guides are available in a Corrosion Resistant version. Rails and Rollers are made from SUS440C Corrosion resistant steel with the V rails having additional Nickel plating applied to the rails. Roller cages are manufactured from SUS 304 Stainless Steel.