Trapezoidal Lead Screws

Trapezoidal Threads using the 30 degree thread profile are the most common form used for Lead Screw and Power screw applications. They offer high strength and ease of manufacture. They are typically found where large loads are required. Available in Right and Left hand variations with Standard Flanged Bronze Nuts available of the shelf.

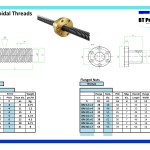

Trapezoidal single start thread designations are the letters “TR” followed by the Major Diameter in mm and then the pitch in mm separated by an “X”. Thus, a “TR 14 x 3” Trapezoidal thread has a major diameter of 14 mm and a pitch of 3 mm.

Trapezoidal v’s Acme

Trapezoidal lead screws and nuts are power transmission screw threads similar to the Acme series but made to metric dimensions and standards. Trapezoidal lead screws look like Acme screws and have the same stout thread form and the same robust and durable features as the Acme series.

One subtle but important difference between ACME and Trapezoidal thread is the flank angle. Acme threads have 14 1/2 degree flank angles (29 degrees included) whereas Trapezoidal threads have 15 degree (30 degrees included) flank angles. This means that single point tooling used to produce Acme threads both internal and external cannot be used in making Trapezoidal threads and vice versa. Users must be careful when measuring all thread features to determine whether a given specimen is Trapezoidal or ACME as the two can be easily confused. For example, 1 – 5 ACME has a Major Diameter of 25.4 mm and a pitch of 5.08 mm. It is quite easy to mistake this size for a TR 25 x 5 Trapezoidal. A visual examination would not be accurate enough to distinguish these two sizes – caliper, micrometer or thread comparator measurements would have to be made.

Advantages and Features

BT precision’s rolled thread Trapezoidal Lead screws and high performance Trapezoidal nuts are combined to provide the optimum performance available in this type of power screw. The highly burnished surface finish of the screw and low friction bronze and plastic nuts yield a smoother, less abrasive action than conventional cut Trapezoidal screws. Improved wear and surface properties insure users a longer service life and quieter operation, requiring less power in a wide variety of applications.

Materials and Processes

All BT Precision Trapezoidal lead screws are made of special quality low carbon steel. Alternate screw materials are 304 type stainless steel.

Trapezoidal lead screws are cold formed using a unique, highly accurate thread rolling process which guarantees a smooth, high quality thread. The thread rolling process eliminates the interrupted grain flow of conventional cut threads, thereby increasing yield, ultimate, and fatigue strengths.

Selection

With over 20 sizes in right and left hand versions, BT Precision offers the a large range of diameters and pitches of Trapezoidal lead screws. Standard nuts are offered in bronze and plastic. Bronze and plastic nuts are offered in universal sleeve style and in threaded mount style for mating with steel flanges.

Nut Selection

When selecting the right nut for an application, there are a few things to keep in mind. Bronze nuts provide superior service at high working loads. They should be well lubricated with a good quality, Extreme Pressure (EP) grease compatible with the operating environment. Plastic nuts can be used without lubrication and are popular for low load applications.

Self-Locking

Most Trapezoidal screws have lead angles of 5° or less making them self-locking. Trapezoidal screws will not back drive under most conditions. This eliminates the need for brakes or other holding devices to sustain loads after they have been positioned. All other screws except Acme series require some braking means to prevent backdriving.

Low Cost

All sizes of Trapezoidal screws are made in large volume and their widespread popularity makes them the least costly of all power screws.

Efficiency

Mechanical efficiencies for Trapezoidal lead screws range from 20% – 40% depending upon the lead angle, coefficient of friction and nut material. Plastic nuts offer approximately 10% – 20% better efficiency than bronze because of their lower coefficient of friction when running against steel screws.

Mechanical Advantage

Low lead angles offer a high mechanical advantage for Trapezoidal screws. This means they require less input torque for a given load than other power screws. The finer the threads for any given diameter, the greater the mechanical advantage.

Typical Applications

BT Precision’s Trapezoidal lead screws and nuts are widely used and well suited for both manual and power drive applications including:

Feed Screw

Pharmaceutical machinery

Packaging machinery

Machinery for global markets

Slide drives

Metric valve stems

Medical device drives

Farm machinery

Screw press drives

Screw jacks