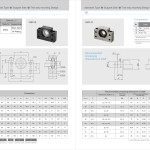

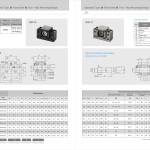

Ball Screw Support Units

GMT Support Units comes in 4 main types: models GAK, GBK, GEK, GFK, which are standardised for standard Ball Screw assemblies provided with industry standard finished shaft ends, and models BK and BF, which are standardised for ball screws in general.

The Support Unit on the fixed side contains a JIS Class 5-compliant angular bearing provided with an adjusted preload. The miniature type Support Unit models GEK/GFK 4, 5 and 6, in particular, incorporate a miniature bearing with a contact angle of 45 deg. developed exclusively for miniature Ball Screws. This provides stable rotational performance with a high rigidity and accuracy.

The Support Unit on the supported side uses a deep-groove ball bearing.

The internal bearings of the Support Unit models GAK, GEK, GFK and GBK contain an appropriate amount of lithium soap-group grease that is sealed with a special seal. Thus, these models are capable of operating over a long period.

All units are available in corrosion resistant Nickle plated versions.

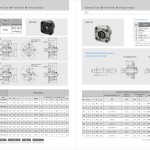

Bearing Characteristics

To ensure the rigidity balance with the Ball Screw, the Support Unit uses an angular bearing (contact angle: 30 deg. DF configuration) with a high rigidity and a low torque. Miniature Support Unit models GEK/GFK 4, 5 and 6 are incorporated with a miniature angular bearing with a contact angle of 45 deg. Developed exclusively for miniature Ball Screws. This bearing has a greater contact angle of 45 deg. And an increased number of balls with a smaller diameter. The high rigidity and accuracy of the miniature angular bearing provides the stable rotational performance.

Support Unit Shapes

Square and round shapes are available for the Support Unit to allow selection according to the intended use.

GBK, GEK, GFK, GAK having convenient matching Floating Support units.

Compact and Easy Installation

The Support Unit is compactly designed to accommodate the space in the installation site. As the bearing is provided with an appropriately adjusted preload, the Support Unit can be assembled with a Ball Screw unit with no further machining. Accordingly, the required man-hours in the assembly can be reduced and the assembly accuracy can be increased.